History

After a split with the earth drilling machines industry, the organization was first continued under the name Kuiken N.V. in Emmeloord and eventually continued independently in 1990 under the leadership of Aad Schilperoord, who is still closely involved with the organization. Bram Muurlink has been director and owner since 2009. With his many years of experience within the organization and his love for technology and innovation, he has been able to develop Conrad into the international organization it is today.

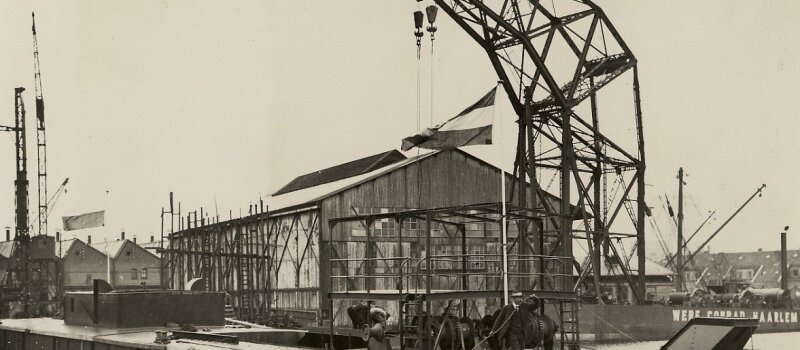

Start of the Conrad shipyard

On April 1, 1883, Thomas Figee founded the Werf Conrad. The name Conrad was a tribute to Frederik Willem Conrad, who had a role in the digging of the Suez Canal and who in 1847 was also one of the founders of the Royal Institute of Engineers. In 1887, a participation of C.T. and you. Stork made the first connection with the company Stork from Hengelo. This band became much more extensive in the years that followed.

Conrad & Stork

The department of the Stork Brothers, "Stork Hijsch" in Hengelo, is transferred to Haarlem to continue building increasingly larger cranes on the east side of the Spaarne. All parts of Conrad were moved to this site, except for the yard itself. Only ten years or later does the name change to Conrad Stork.

On to the polder

The earthmoving department, where drilling machines, drilling tools and flushing pumps were produced, is sold to a group of companies; the company Kuiken BV in Emmeloord, Kemmach BV in Lemmer and PT Sarkana in Jakarta (Indonesia). The deep drilling department continued under the name Arkana BV in Emmeloord.

Conrad Stanen is on the map

The deep drilling department is purchased by Stanen Europe BV in Emmeloord. This company bought the name Conrad from Schelde-Rademakers BV in 1994-1995 and then changed its name to Conrad - Stanen BV. From that time on, the organization has been led by Aad Schilperoord, who will remain involved with the organization for a long time to come.

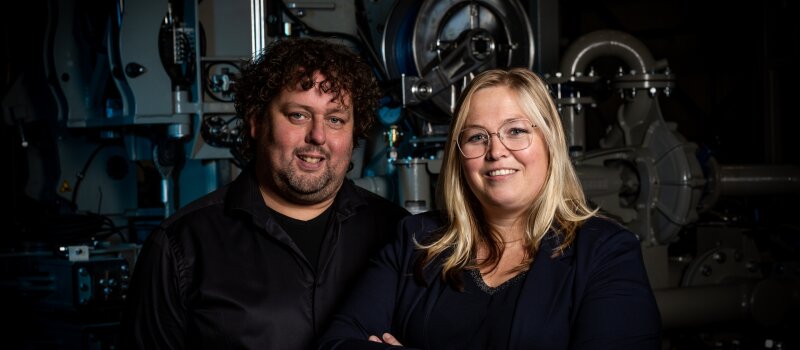

Bram Muurlink in charge

In 2009 Bram Muurlink - who had already been working in the workshop for a number of years - started as director-owner of Conrad. Under his vision, the organization is taking major steps towards the future, mainly supported by the technical knowledge and the high demand for innovative solutions in a conservative niche market.

Responding to the growing demand

In order to respond to the increased demand for drilling rigs, Conrad was forced to completely change the way of supplying and assembling. Previously, all construction parts were supplied from the Eastern Bloc countries and adapted and mounted on many details. The machine was then disassembled and preserved so that the final assembly could take place. A time consuming and inefficient process. Conrad chose to manufacture the various parts from the 3D drawing himself or to purchase them from local construction companies. The necessary conservation now also took place at a local company, so that the construction parts could be put into final assembly directly at Conrad Stanen. It didn't do Conrad any harm.

Acquisition of Kefdrill and DCC

As of January 1, 2017, Conrad will take over the drilling-related activities of Kefdrill Boortechniek BV from Hoevelaken. Kefdrill Boortechniek bv is a renowned Dutch company, founded in 1986 and specialized in the design and manufacture of sediment drilling machines for environmental research, water extraction, geotechnical research and their applications. The spearhead for the organization is the development of customer-specific, reliable machines for applications in soil research, water extraction, cold-heat storage (KWO systems) and well-water drainage. The specialization in environmental and soil research in particular was a reason for Conrad to sit down with Kefdrill. In addition to Kefdrill, the line of vertical augers from DDC will also be taken over from 15 February; the famous Wizard model. Specialization is essential to be able to play a role worldwide, and we achieved that with the move to Offshore drilling.

Huge growth in production capacity

The demand for drilling machines in the field of well drainage, geothermal heat, soil research and well drilling continued to increase in the years that followed. Due to the population growth, more and more houses were needed and at the same time the regulations regarding augers were becoming stricter. Here too, innovation had to provide new solutions, a more efficient approach and sustainable processes. In 2020, the Emmeloord branch was again expanded with a complete workshop for the Service & Maintenance department, which would later continue under the name Conrad Service Solutions. From that moment on, Conrad had facilities totaling 2,700 m2. A gigantic step for production. In 2003, Conrad could only handle two new augers. Since 2020, Conrad has been designing and building at least twenty installations a year. Invariably equipped with the most modern techniques in the field of safety, ease of use and efficiency.